Training

Welding and Fabrication

A Welding and Fabrication course equips students with the skills needed to join and shape metal components for various applications. The course covers welding techniques such as MIG, TIG, and arc welding, along with fabrication methods including cutting, bending, and assembling metal structures. Students learn to read blueprints and follow safety protocols to ensure precise and secure welds. Graduates are prepared for careers in manufacturing, construction, and industrial maintenance, with the ability to produce high-quality metalwork and adhere to industry standards.

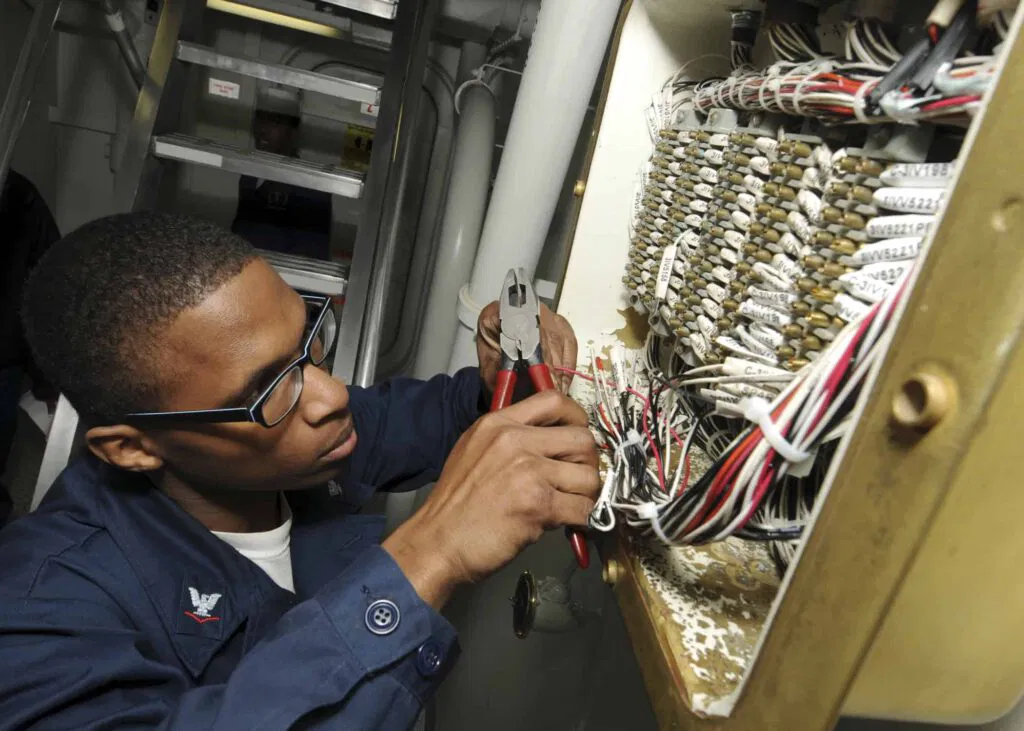

Electrical Installation and Maintenance

An Electrical Installation and Maintenance training course equips individuals with the skills to safely install, maintain, and repair electrical systems in various settings. Covering essential topics like electrical theory, safety practices, wiring methods, and troubleshooting, the course combines theoretical knowledge with hands-on training. Participants learn to use tools and read blueprints, preparing them for careers as residential, commercial, or industrial electricians. Successful completion often leads to certification, qualifying graduates for entry-level positions in the electrical field.

Machinist

The machinist training course provides comprehensive instruction in precision machining techniques and operations, equipping students with the skills necessary to operate and maintain various machine tools such as lathes, milling machines, and grinders. The curriculum covers a range of topics, including blueprint reading, measurement, and cutting tool technology, with a strong emphasis on practical, hands-on experience. Students learn to perform precise machining tasks, troubleshoot common issues, and adhere to industry safety standards. The course aims to prepare individuals for careers in manufacturing and machining by developing their technical expertise and problem-solving abilities.